Regenerative Air Preheater is an advanced and energy-efficient heat recovery device widely used in thermal power plants, industrial boilers, and process heating systems to boost thermal performance. This rotating heat exchanger plays a crucial role in improving overall combustion efficiency by transferring waste heat from flue gases to the incoming combustion air. As global industries face increasing pressure to reduce fuel consumption and greenhouse gas emissions, regenerative air preheaters have become a critical technology in achieving higher energy efficiency and sustainable operation.

Unlike conventional recuperative air preheaters, regenerative systems operate on a cyclical heat transfer principle, wherein a rotating heat storage matrix alternately absorbs and releases heat. This continuous thermal regeneration allows for superior heat recovery, reduced fuel costs, and lower emission outputs. RAPH units are especially valuable in high-capacity plants where preheating combustion air can significantly impact the boiler’s thermal cycle and efficiency.

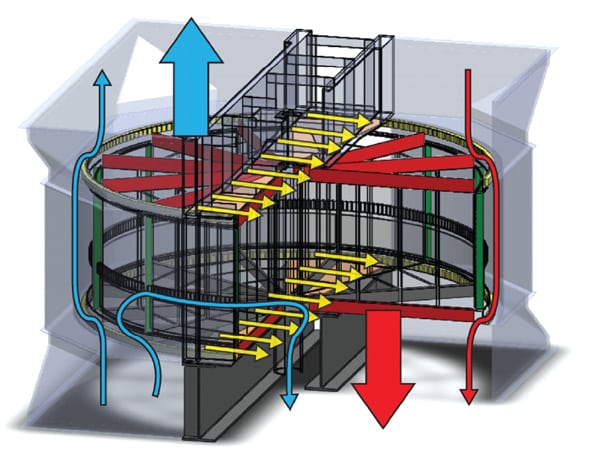

Working Principle: How It Operates

Basic Functionality:

The RAPH uses a slowly rotating matrix made of metal or ceramic components that stores heat from hot flue gases and releases that heat to incoming cold air.

- Flue Gas Side:

- Hot exhaust gases from the combustion chamber pass through part of the rotor.

- Heat is absorbed and stored in the heat transfer elements (often called baskets or matrix plates).

- Combustion Air Side:

- As the rotor turns, the heated matrix moves into the cold air stream.

- The preheated matrix transfers the stored thermal energy to the incoming combustion air.

- Continuous Rotation:

- This process occurs continuously with the rotor typically turning at 1 to 3 RPM.

- The rotor is divided into multiple sectors to handle different zones of heat transfer and sealing.

Types of Designs:

- Rotary RAPH (Tri-sector and Quad-sector): Most common in large thermal power stations.

- Stationary-Element Type: Used in smaller units, with moving dampers instead of a rotor.

Unique Technical Features

Segmented Heat Exchange Baskets:

- Easy to replace individual segments without dismantling the entire unit.

- Layered basket design offers tuning for pressure drop and heat transfer efficiency.

Material Innovation:

- Advanced materials like corrosion-resistant alloys, enamel-coated steel, or ceramic matrix composites increase durability.

- Glass-lined surfaces used in highly corrosive environments, especially where sulfuric acid dew point is an issue.

Variable Speed Drive (VSD):

- Some RAPHs integrate VFD-controlled motors to optimize rotor speed based on boiler load and flue gas temperature.

Dual Rotor Configuration:

- For ultra-high efficiency applications, twin-rotor designs allow for staged air preheating, reducing NOx emissions and improving boiler response.

Performance Benefits

Fuel Savings:

- Preheating combustion air reduces fuel requirement to reach operating temperatures.

- Typical increase in boiler efficiency by 8–12%.

Emission Reduction:

- Reduced fuel combustion = lower CO₂, SOx, and NOx emissions.

- Especially effective in low-NOx combustion systems.

Improved Draft & Flow:

- Optimized matrix geometry ensures low pressure drop while maximizing heat recovery.

Maintenance Efficiency:

- Access doors, modular baskets, and self-cleaning (soot blowing) reduce downtime.

- Long operating life (20+ years in well-maintained systems).

Limitations and Challenges of Regenerative Air Preheater

Ash Fouling:

- Ash-laden gases can clog matrix elements.

- Requires frequent cleaning or advanced soot blowing arrangements.

Acid Dew Point Corrosion:

- In coal-fired plants, SO₂ + moisture → H₂SO₄.

- If the metal surface drops below the acid dew point (~130°C), corrosion accelerates.

Rotor Warping:

- Uneven thermal expansion can deform the rotor.

- Addressed by sectioned or floating rotor assemblies and gradual startup procedures.

Leakage:

- Seal wear leads to cross-contamination, reducing thermal effectiveness.

- Constant seal inspection and replacement needed.

Regenerative Air Preheater technology represents a vital pillar in modern energy conservation strategies for industrial heating systems, particularly in coal-fired power plants, waste incinerators, and process furnaces. By efficiently capturing and reusing waste heat from exhaust gases, RAPH units substantially improve the thermal efficiency of combustion processes while simultaneously lowering fuel consumption and emissions such as CO₂, SOx, and NOx.

The combination of innovative design, such as tri-sector zoning, segmented baskets, and low-leakage seals, with advanced materials like enamel-coated steel and ceramics, makes regenerative air preheaters well-suited for harsh operating environments. Additionally, the integration of digital monitoring systems, variable-speed drives, and predictive maintenance tools allows industries to enhance reliability, reduce unplanned downtime, and extend equipment lifespan.