Hypersonic vehicles Cooling System which operate at speeds exceeding Mach 5, represent the cutting edge of aerospace innovation—yet they also introduce some of the most extreme engineering challenges known today. Among these, managing the immense thermal loads caused by atmospheric friction and shockwave interactions stands as a critical concern. As surface temperatures soar beyond 2,000°C, conventional cooling techniques become inadequate. This has led to the evolution of advanced, multi-tiered thermal management systems designed specifically for hypersonic environments. From regenerative and ablative cooling to transpiration and cryogenic techniques, each system plays a vital role in preserving structural integrity, safeguarding internal electronics, and enabling the vehicle to withstand the rigors of hypersonic flight.

Why Cooling is Vital in Hypersonic Vehicles

Unprecedented Thermal Loads

- Friction and shockwaves heat the vehicle’s surface to 1,500°C–3,000°C — hotter than molten lava.

- This heat can destroy materials, weaken structures, and damage onboard electronics.

Mission-Critical Protection

- Cooling ensures:

- Structural integrity of nose cones, leading edges, and engine inlets.

- Operational stability of guidance systems and sensors.

- Safety for manned missions or sensitive payloads.

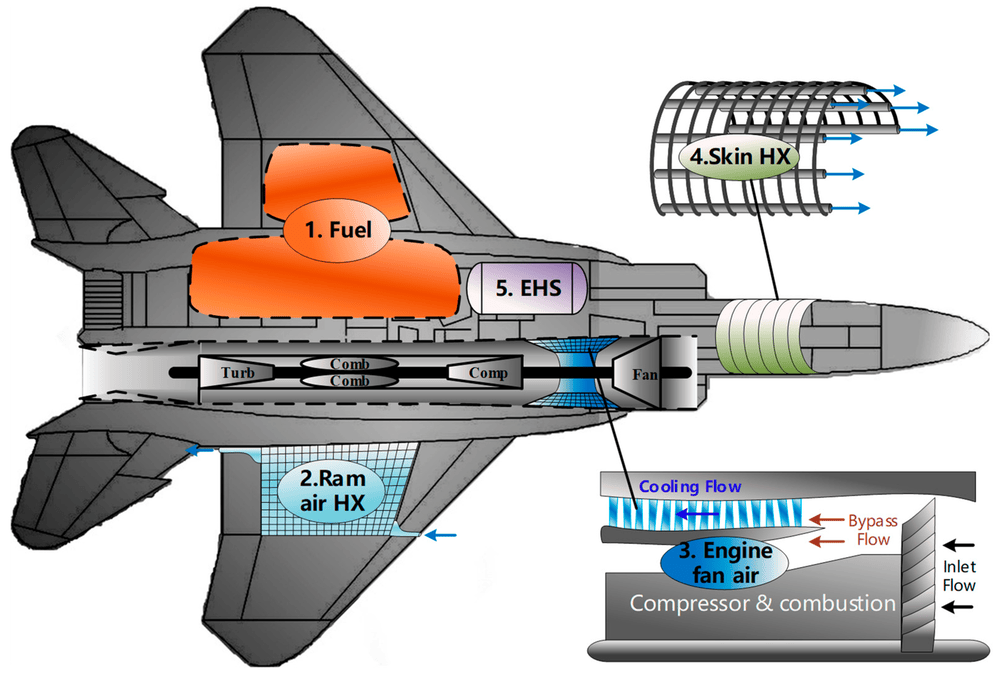

Advanced Cooling Techniques

Hypersonic vehicles don’t rely on just one cooling strategy — they integrate multiple active and passive systems. Here’s a breakdown:

Regenerative Cooling (Internal Active Cooling)

How it works:

Fuel (usually liquid hydrogen or kerosene) flows through cooling channels embedded around the hottest parts of the vehicle (like the engine wall or nose cone). As it passes through, it absorbs heat, keeping the structure cool, and becomes preheated fuel for combustion.

Applications:

- Scramjet engines

- Rocket-based combined cycle engines

- Nozzles and combustor walls

Advantages:

- Dual-function: cools and preheats fuel

- Lightweight and efficient

- Reduces need for separate cooling systems

Transpiration Cooling (Surface Bleed Cooling)

How it works:

Coolant gas or vapor bleeds through tiny pores in the surface, forming a thin protective layer between the vehicle and the external hot gas. This “film” absorbs and deflects heat, keeping the structure cooler.

Materials used:

- Porous ceramic composites

- Sintered metals

- Carbon-carbon materials with engineered porosity

Advantages:

- Effective for leading edges and nose tips

- Lightweight

- Continuously refreshes the thermal barrier

Ablative Cooling (Passive, Sacrificial Protection)

How it works:

Special materials intentionally melt, burn, or sublimate when heated. This phase change absorbs heat and carries it away as the material erodes. Often used in reentry vehicles and missiles.

Ablative Materials:

- AVCOAT (used in Apollo capsules)

- PICA (Phenolic Impregnated Carbon Ablator)

- Carbon-phenolic composites

Advantages:

- Simple, no moving parts

- Works at extremely high temperatures

- Excellent for short-term hypersonic events

Cryogenic Cooling (Fuel as Coolant)

How it works:

Cryogenic fuels like liquid hydrogen (LH₂) have extremely low boiling points. Before combustion, these fuels are used to cool hot surfaces, systems, and electronics.

Benefits:

- Lowers boil-off losses

- Reduces thermal stress

- Essential for fuel efficiency and safety in hydrogen-powered vehicles

Heat Pipes and Thermal Spreaders

How it works:

Sealed tubes filled with a working fluid (like ammonia, water, or sodium). As the fluid vaporizes at the hot end, it moves heat to the cooler end where it condenses and releases it.

Used in:

- Leading edges

- Electronic enclosures

- Airframe panels

Advantages:

- Passive, high thermal conductivity

- No pumps or moving parts

- Spreads heat evenly

Global Applications and Use Cases

Military & Aerospace

- Hypersonic Glide Vehicles (HGVs): DF-ZF (China), Avangard (Russia)

- Scramjet Missiles: X-51A Waverider (USA)

- Space Re-entry Vehicles: NASA Orion, ISRO’s RLV-TD

- Future Hypersonic Aircraft: DARPA Falcon HTV-2, Lockheed SR-72

Reusable Spacecraft

- Cooling systems are critical for reusable systems to withstand multiple missions without needing full TPS replacement.

Thermal Design Engineering Challenges

Extreme Temperature Differentials

- The outer skin may reach 3000°C while internal electronics must stay below 100°C.

- Requires multi-layer insulation, thermal isolation, and active cooling.

Balancing Weight & Protection

- Every cooling layer adds weight, reducing fuel efficiency.

- Engineers must balance cooling effectiveness vs. vehicle performance.

Transient Thermal Loads

- Temperatures change rapidly with speed, altitude, or maneuvering.

- Cooling systems must react in milliseconds.

Material Fatigue & Erosion

- Continuous heat cycles cause oxidation, microcracks, and thermal expansion issues.

- Regular testing and new material development are required.

Hypersonic Vehicle Cooling System technology is deeply intertwined with our ability to manage heat at unprecedented levels. Cooling systems in these vehicles are no longer optional—they are essential components of the overall design architecture. Through a combination of smart materials, innovative thermal engineering, and integrated cooling methods, modern hypersonic platforms can now achieve both high performance and long-duration survivability. As global aerospace programs continue to push speed and altitude boundaries, future breakthroughs in thermal management—such as AI-driven heat control and phase-change materials—will determine the pace of progress. In this high-stakes domain, superior cooling isn’t just about efficiency—it’s the key to operational success and mission viability.