Introduction

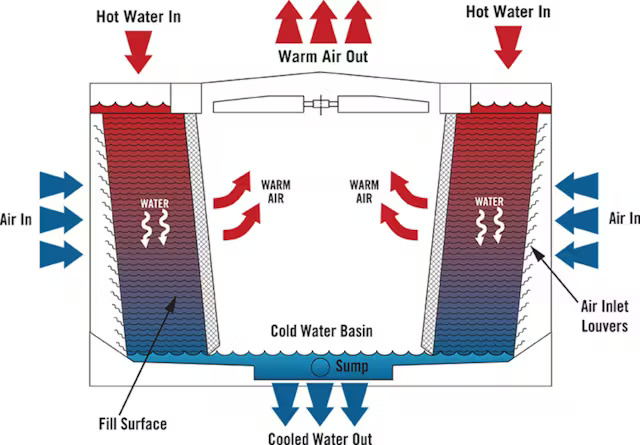

Evaporative cooling towers play a vital role in industrial and HVAC systems, providing efficient heat dissipation by using water evaporation to cool circulating water. As industries seek ways to reduce energy consumption and improve environmental sustainability, optimizing cooling tower efficiency has become essential. Enhancing the design and operational features of these systems can lead to significant performance gains, from advanced fill media and improved airflow to smart controls and water quality management. These innovations not only boost energy efficiency but also extend the lifespan of equipment, aligning with the growing demand for eco-friendly and cost-effective cooling solutions.

Advanced Fill Media Design

- Description: Fill media increases the surface area of water, allowing more air-water contact for effective evaporation.

- Enhancements: Upgrading to high-performance fill media, such as structured or cellular fills, improves water distribution and air flow, increasing evaporation rates.

- Benefits: Better heat exchange, reduced energy consumption, and lower water usage by improving the cooling capacity of the tower.

Optimized Airflow Management

- Fan Efficiency: High-efficiency fans, such as axial fans with optimized blade profiles, reduce energy usage while maximizing airflow through the tower.

- Variable Frequency Drives (VFDs): Installing VFDs on fans allows precise control of airflow based on cooling demand, optimizing energy consumption.

- Air Inlet Design: Proper design of air inlets minimizes air resistance and improves circulation, which helps maintain efficient tower operation.

Water Distribution Improvements

- Spray Nozzle Upgrades: Efficient nozzles distribute water evenly over fill media, ensuring maximum air-water interaction and better cooling.

- Anti-Clogging Nozzles: Installing anti-clogging nozzles can prevent blockages that disrupt water distribution, reducing downtime and maintenance needs.

- Header System Optimization: Improving the layout and design of the header system helps maintain consistent water flow across all parts of the fill media.

Drift Eliminators

- Description: Drift eliminators capture water droplets in the air exiting the tower, reducing water loss and minimizing environmental impacts.

- Enhancements: Advanced designs, such as multi-layered drift eliminators, increase water recovery while maintaining airflow.

- Benefits: Reduced water consumption and lower risk of chemical drift, especially important for towers located near populated or sensitive areas.

Water Quality Management

- Water Treatment Systems: Effective water treatment reduces scaling, fouling, and biological growth, all of which impair cooling efficiency.

- Chemical Additives: Adding anti-scaling or anti-corrosion chemicals helps prolong the life of tower components and maintain efficiency.

- Filtration and Softening: Removing particulates and minerals from the water helps prevent build-up on fill media, maximizing heat exchange and reducing maintenance costs.

Heat Transfer Surface Enhancements

- Enhanced Materials: Using materials with better thermal conductivity in the fill media, such as certain plastics or metals, can increase the cooling rate.

- Anti-Microbial Coatings: Coatings prevent biological growth on surfaces, reducing maintenance and improving long-term efficiency.

Automation and Smart Control Systems

- Real-Time Monitoring: Sensors and IoT-based systems track parameters like water temperature, humidity, and airflow in real time.

- Automated Control: Automated adjustments to fan speed, water flow, and chemical dosing optimize performance based on current operating conditions.

- Predictive Maintenance: Smart systems can analyze data trends to predict and prevent potential issues, minimizing downtime and enhancing efficiency.

System Insulation and Enclosures

- Description: Proper insulation and enclosure of water distribution pipes and exposed parts minimize heat loss to the surrounding environment.

- Benefits: Insulating components helps retain cooling efficiency, especially in applications where external temperatures fluctuate significantly.

Energy Recovery Systems

- Heat Recovery: Capturing and reusing heat from warm water exiting the tower can reduce energy needs for other heating processes.

- Co-Generation: Cooling towers integrated with co-generation systems can utilize waste heat, further improving energy efficiency across the plant or facility.

Regular Maintenance and Cleaning

- Scaling and Fouling Prevention: Regularly removing scale and biofilm build-up ensures that the fill media and other components operate at maximum efficiency.

- Fan and Motor Maintenance: Routine maintenance of fans, motors, and VFDs ensures consistent airflow and prolongs the life of mechanical components.

- Seasonal Inspections: Seasonal inspections and maintenance help prevent issues from temperature fluctuations, ensuring uninterrupted operation and efficiency.

Conclusion

By adopting these design and operational enhancements, evaporative cooling towers can achieve improved efficiency, reducing energy consumption and water use. Innovations such as advanced fill media, efficient fans, automated control systems, and improved water management significantly contribute to optimized cooling performance. Regular maintenance and smart monitoring further ensure longevity and reliability, making these towers more sustainable and cost-effective. Adopting these practices aligns with both environmental responsibility and operational cost savings, positioning evaporative cooling towers as efficient solutions in modern industrial and HVAC applications.