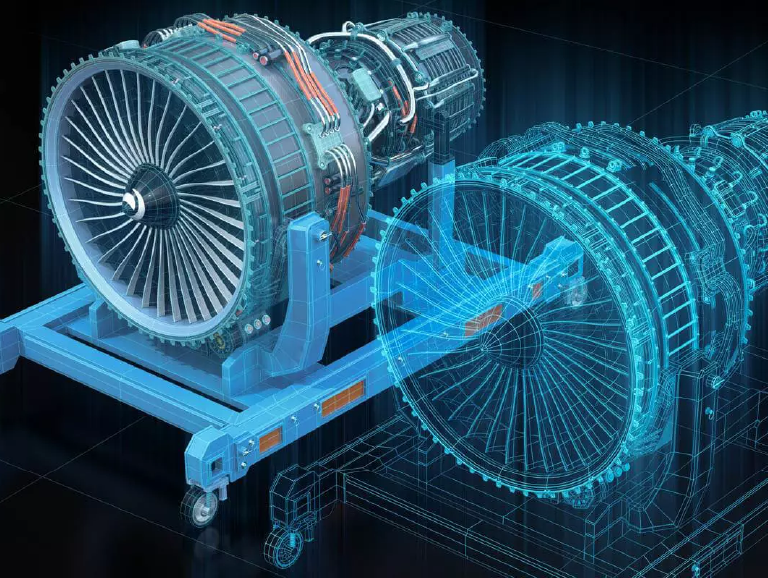

Digital Twin in Heat Exchangers represents a groundbreaking shift in the way thermal equipment is designed, operated, and maintained. By creating a virtual replica of a physical heat exchanger—whether it’s plate and frame, shell and tube, or finned coil—the digital twin brings together real-time sensor data, advanced simulation models, and artificial intelligence to deliver precise insights into performance, efficiency, and potential failure points.

In traditional setups, engineers often rely on manual inspections, fixed maintenance schedules, and estimated performance metrics. However, digital twins transform this process by offering live feedback loops and predictive analysis based on actual operating conditions. This enables plant managers and maintenance teams to optimize cleaning intervals, minimize energy losses, and detect issues such as scaling, fouling, or pressure drops before they impact operations.

What Exactly Is a Digital Twin for Heat Exchangers?

A Digital Twin of a heat exchanger is a living digital representation of the physical exchanger, continuously updated with real-time data from sensors and operational logs. It includes:

- 3D geometrical models of the exchanger’s internal and external design.

- Live data inputs from temperature sensors, flow meters, pressure gauges, and vibration monitors.

- Mathematical and physical models that simulate heat transfer, fouling, fluid dynamics, and mechanical stress.

- Analytics and AI models to interpret patterns, anomalies, and trends.

Unlike a static model, this digital twin is bi-directional — not only does it receive and process real-world data, it can influence control decisions back in the physical system (like modifying flow rates, scheduling cleaning, or alerting for imminent failure).

The Building Blocks of a Heat Exchanger’s Digital Twin

A complete digital twin of a heat exchanger is built using five key layers:

Physical Layer (The Real Heat Exchanger)

- Includes all tangible components: plates/tubes, gaskets, baffles, frame, sensors, etc.

Sensing and Data Layer

- Data collected from smart sensors:

- Inlet/outlet temperature

- Flow rate

- Pressure drop

- Fouling thickness

- Vibrations (for mechanical wear)

Digital Model Layer

- Contains:

- CAD or BIM model of geometry

- Finite element or CFD-based heat transfer model

- Real-time simulators of fluid flow and pressure

Analytics & Intelligence Layer

- Uses:

- Machine learning algorithms to detect drift or degradation

- Predictive models for cleaning cycles, failure points, thermal performance

- Anomaly detection systems for leaks, blockages, scaling

Visualization & Cloud Integration Layer

- The user interface/dashboard:

- Web portals or apps for real-time visualization

- Cloud storage for historical data trends

- Edge computing for on-site processing and faster response

Working Example: Digital Twin in Action

Real-time Scenario:

Let’s consider a plate and frame heat exchanger used in a dairy processing plant.

- Sensors continuously capture data on milk temperature, hot water inlet, pressure, and flow rate.

- The digital twin receives data every 5 seconds and runs a simulation to calculate:

- Real-time heat transfer coefficient (U-value)

- Scaling factor and fouling resistance

- Predicted temperature at the outlet (compared to actual)

Result:

- If the U-value drops below a threshold, the system predicts fouling buildup.

- Maintenance is scheduled before product quality is affected.

- Energy input is recalculated and reduced by 12%, avoiding thermal loss.

Deep Benefits of Using Digital Twins in Heat Exchangers

Predictive Maintenance & Reduced Downtime

- Traditional cleaning happens on fixed intervals, often too early or too late.

- Digital twins calculate actual fouling trends and notify only when cleaning is required.

- Reduces unnecessary downtime, saving thousands in lost production hours.

Optimized Thermal Performance

- Adjusts pump speed, flow rate, or fluid temperature to maintain ideal heat transfer efficiency.

- Offers live tuning suggestions based on ambient conditions or seasonal changes.

Sustainability & Energy Savings

- Identifies underperforming units consuming excessive energy.

- Helps with heat recovery optimization, reducing carbon footprint and energy bills.

Root Cause & Failure Mode Analysis

- Analyzes causes of:

- Uneven flow distribution

- Blocked passages

- Gasket failures

- Scaling or corrosion

- Simulation tools help visualize worst-case scenarios, aiding safer designs.

Remote Monitoring and Global Scalability

- Enables remote control and alerts from multiple plants.

- Ideal for companies operating heat exchangers in distributed facilities or offshore rigs.

Digital Twin in Heat Exchangers is not just a digital representation—it is an intelligent, self-evolving system that offers unprecedented control over thermal processes. It bridges the physical and digital worlds to ensure that each exchanger runs at peak efficiency, adapts to process variations, and responds proactively to maintenance needs.

As industries move toward smart manufacturing, net-zero emissions, and predictive asset management, digital twin technology is becoming an essential tool rather than a luxury. It enhances decision-making with accurate, real-time data, improves the safety and longevity of critical assets, and supports compliance with energy regulations and operational standards.