Introduction

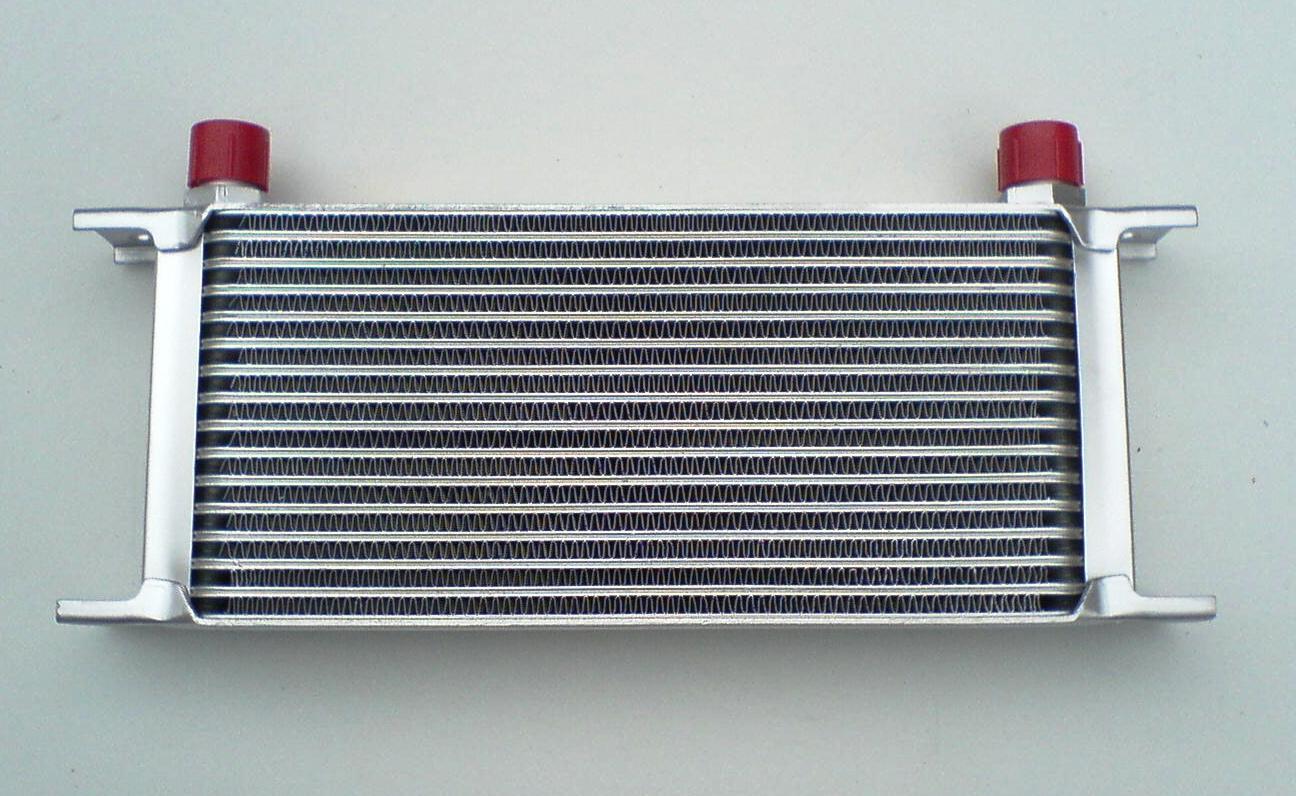

Compact oil cooler is a highly efficient, space-saving heat exchanger specifically engineered to remove excess heat from lubricating, hydraulic, or transmission oil. Despite their smaller physical footprint, these coolers deliver high thermal performance, making them ideal for equipment where space, weight, and efficiency are critical concerns. Whether in high-speed automotive engines, marine propulsion systems, hydraulic power packs, or CNC machine tools, compact oil coolers provide precise and reliable temperature control to prevent overheating and oil breakdown.

Designed for flexibility and efficiency, compact oil coolers come in various configurations such as air-cooled, water-cooled, plate-type, and shell-and-tube types. Their robust construction and versatile installation options make them indispensable in today’s performance-driven, space-sensitive industries.

Working Principle of Compact Oil Coolers

A compact oil cooler operates based on the heat exchange principle, where heat from hot oil is transferred to a cooler medium (either air or water), thereby lowering the oil’s temperature. Here’s how it works step by step:

- Hot oil enters the oil cooler through an inlet port.

- The oil flows through a series of internal channels, plates, or tubes within the cooler.

- Simultaneously, a cooling medium (air or water) passes over or around the oil path, absorbing heat.

- The heat is then dissipated into the atmosphere (in air-cooled systems) or carried away by the water (in water-cooled systems).

- Cooled oil exits the cooler and is returned to the main system for reuse.

The compact design ensures that even in tight spaces or portable applications, the oil remains at safe, efficient operating temperatures.

Key Features and Benefits of Compact Oil Coolers

- Space-saving design – Ideal for equipment with limited installation space.

- Thermal efficiency – Maintains stable oil temperature for safe operations.

- Improves system performance – Prevents overheating and system breakdowns.

- Quick and easy installation – Lightweight and user-friendly design.

- Low maintenance – Compact coolers are designed for long service with minimal care.

- Compatible with multiple systems – Suitable for hydraulic, lubrication, and engine oil systems.

- Reduces oil oxidation – Prevents oil degradation due to excessive heat.

- Extends machinery lifespan – Protects components from thermal damage.

- Available in air-cooled and water-cooled options – Flexible for diverse setups.

- Enhances cooling efficiency in mobile or remote operations.

Applications of Compact Oil Coolers

Compact oil coolers are used across various industries and machines that require oil cooling in a confined space. Key applications include:

Hydraulic Systems

- Hydraulic power packs, press machines, injection molding machines, and cranes.

Automotive and Motorsports

- Engine oil coolers, transmission oil coolers, racing cars, off-road vehicles.

Marine Equipment

- Cooling engine oil, gearbox oil, and lube oil in marine diesel systems and offshore equipment.

Construction and Mining Machinery

- Excavators, loaders, bulldozers, and drilling machines.

Machine Tools and CNC Equipment

- Oil cooling for precision machining, spindles, and lubrication systems.

Compressors and Blowers

- Cooling oil in screw compressors, air compressors, and refrigeration systems.

Wind Turbines and Renewable Systems

- Compact cooling in nacelle-mounted systems where space is limited.

Conclusion

Compact oil cooler means not only ensuring your system runs smoothly but also enhancing energy efficiency and equipment reliability in the long term. Whether it’s for a high-speed automotive application, a hydraulic press in a factory, or a marine engine operating in harsh environments, a compact oil cooler offers peace of mind through consistent thermal control and mechanical protection.

In conclusion, investing in a well-engineered compact oil cooler is not just a technical decision—it’s a strategic choice that contributes directly to equipment longevity, operational stability, and cost savings, especially in industries where every inch of space and every degree of heat matters. As systems become more advanced and space becomes a premium, compact oil coolers represent a smart, reliable, and forward-looking solution for thermal management.