INTRODUCTION

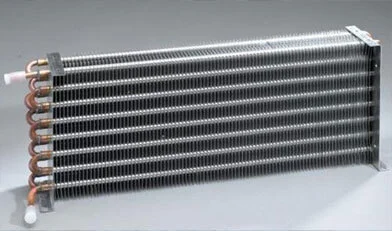

Compact fin-tube assemblies are integral components in modern thermal management systems, playing a pivotal role in a wide array of industries, from HVAC systems to industrial cooling applications. These assemblies are engineered to maximize heat transfer within a minimal space, providing enhanced thermal efficiency. The design typically consists of tubes fitted with fins, which increase the surface area available for heat exchange. As energy conservation and space optimization become more critical in contemporary engineering, compact fin-tube assemblies offer a solution that balances both, enabling efficient heat dissipation while reducing the physical footprint of the system. They are particularly popular in applications where high thermal performance is required in confined spaces, such as refrigeration, automotive, and air conditioning systems.

Key Features of Compact Fin-Tube Assemblie:

- Enhanced Heat Transfer: The primary function of a compact fin-tube assembly is to optimize heat exchange between the fluid inside the tubes and the surrounding medium (such as air or another liquid). The fins attached to the tubes provide additional surface area for heat transfer. As the fluid inside the tube circulates, it transfers heat to the fin surfaces, which then dissipate it to the surrounding environment. The increased surface area allows for efficient thermal management, making these assemblies ideal for high-performance cooling or heating systems.

- Space Efficiency: Compact fin-tube assemblie are specifically designed to be space-saving while providing enhanced thermal performance. Their compact design is advantageous in environments where space is limited, such as automotive applications or air conditioning systems. These assemblies reduce the need for larger, bulkier heat exchangers, which would otherwise take up more room and increase the weight of the system. By using compact fin-tube assemblie, engineers can create more efficient systems without compromising on performance or taking up additional space.

- Durability: Compact fin-tube assemblie are built to endure harsh operating conditions. They are often made from corrosion-resistant materials such as aluminum, copper, or stainless steel, which increases their lifespan and reliability in demanding environments. These materials resist mechanical wear and environmental factors like moisture and temperature fluctuations, ensuring that the assemblies perform efficiently for long periods. Furthermore, these assemblies require minimal maintenance, as they are designed to handle regular wear and tear without a significant decline in performance.

- Energy Efficiency: By improving heat transfer, compact fin-tube assemblies help reduce energy consumption across a wide range of systems. These assemblies increase the heat exchange rate, ensuring that systems operate more efficiently with less energy input. For example, in HVAC systems, improved heat transfer means that air conditioning or heating units consume less power while achieving the desired temperature regulation. This energy efficiency translates into reduced operational costs and is especially important as industries and residential applications focus more on sustainability and lowering energy consumption.

- Cost-Effective Design: The compact design and reduced material requirements of fin-tube assemblies make them an affordable option for heat exchange applications. Their simpler construction and the ability to fit into smaller spaces lead to lower manufacturing costs compared to larger, more complex systems. Additionally, the durability of these assemblies reduces the need for frequent repairs or replacements, providing long-term savings for industries that rely on continuous operation and minimized downtime.

Applications of Compact Fin-Tube Assemblies:

- HVAC Systems: In air conditioning and refrigeration systems, compact fin-tube assemblies enhance the cooling or heating efficiency by maximizing heat exchange within the available space. These assemblies are commonly used in evaporators, condensers, and heat pumps, where they efficiently manage the temperature of air or refrigerant fluids circulating through the system.

- Automotive Industry: In the automotive sector, compact fin-tube assemblies are commonly found in radiators, oil coolers, and intercoolers. The compactness of these assemblies allows them to fit into the tight spaces of modern vehicles, helping to regulate engine temperatures and maintain optimal performance. Their efficiency in transferring heat makes them essential in preventing overheating and ensuring that engine components remain cool during operation.

- Industrial Cooling Systems: In industrial processes, compact fin-tube assemblies are used in heat exchangers, cooling towers, and thermal management systems for various machinery. Whether for power plants, chemical processing, or manufacturing plants, these assemblies ensure that excessive heat from the systems is effectively dissipated, preventing overheating and maintaining operational efficiency.

- Heat Exchangers: Compact fin-tube assemblies play a crucial role in various heat exchangers used across industries, including oil and gas, HVAC, and refrigeration. They efficiently transfer heat between fluids, maintaining optimal temperatures and improving system performance. In heat exchangers, these assemblies help maintain the desired temperature differentials, contributing to more energy-efficient operations.

Future Trends and Innovations:

- Advanced Materials: The materials used in compact fin-tube assemblies are expected to evolve with advancements in materials science. Materials such as advanced aluminum alloys, copper composites, and even graphene-based coatings could offer superior thermal conductivity, enhanced durability, and resistance to corrosion. The development of lighter, stronger, and more thermally efficient materials will further enhance the performance of these assemblies, allowing them to function in even more demanding environments.

- Improved Manufacturing Techniques: Innovations in manufacturing technologies such as 3D printing, laser welding, and precision machining are paving the way for even more compact, efficient, and customizable fin-tube assemblies. These techniques allow for the creation of more intricate fin patterns, thinner tubes, and highly precise designs that can further optimize heat transfer while reducing material costs. Customization capabilities will enable the development of assemblies tailored for specific applications, improving overall system performance.

- Smart Technology Integration: Future compact fin-tube assemblies may incorporate smart sensors that monitor temperature, pressure, and fluid flow in real-time. This data could be used to adjust system performance dynamically, optimizing energy consumption and preventing overheating or inefficiencies. Such innovations would allow these assemblies to integrate seamlessly into “smart” HVAC systems or industrial automation setups, enhancing overall system intelligence and performance.

- Eco-Friendly Designs: As industries push for more sustainable solutions, compact fin-tube assemblies are likely to adopt eco-friendly refrigerants and environmentally safe materials. These assemblies may also feature designs that reduce carbon footprints by improving energy efficiency and utilizing recyclable materials. Future designs will focus on reducing waste, lowering emissions, and minimizing the environmental impact of manufacturing processes.

Conclusion:

Compact fin-tube assemblies are crucial components in modern thermal systems, offering high efficiency in heat transfer and space-saving designs. Their applications span across a wide range of industries, including HVAC, automotive, and industrial cooling systems, where efficient temperature regulation is essential. With advancements in materials, manufacturing processes, and smart technologies, these assemblies are set to play an even more prominent role in future thermal management systems. As industries continue to focus on sustainability, energy efficiency, and cost-effective solutions, compact fin-tube assemblies will remain a critical innovation in the pursuit of improved thermal performance.

4o mini