Introduction

Auto Transmission Oil Cooler is a specialized type of heat exchanger designed to remove excess heat from automatic transmission fluid (ATF). As a vehicle operates—especially under heavy load, towing, or in high-temperature environments—the transmission generates significant heat due to friction and fluid movement. This heat, if not controlled, can degrade the transmission fluid, reduce lubrication efficiency, and cause damage to transmission components.

The oil cooler helps maintain the transmission fluid at an optimal temperature range (typically between 160°F to 200°F or 71°C to 93°C), ensuring smooth gear shifting, extended fluid life, and reduced wear and tear of the transmission system.

Working Principle of an Auto Transmission Oil Cooler

- Heat Generation: Transmission fluid becomes hot during gear shifting and power transmission.

- Fluid Circulation: A pump moves the heated fluid from the transmission to the oil cooler.

- Heat Transfer: Inside the cooler, heat from the ATF is transferred to ambient air (air-cooled) or coolant (liquid-cooled), lowering the fluid temperature.

- Return Flow: The cooled transmission fluid flows back into the transmission, ensuring consistent temperature control.

Cooler Location:

- In front of the radiator or air conditioning condenser (external cooler).

- Integrated inside the vehicle’s main radiator (internal or in-tank cooler).

Types of Auto Transmission Oil Coolers

Tube and Fin Coolers

- Traditional and cost-effective design.

- Transmission fluid flows through a series of tubes.

- Fins attached to the tubes help dissipate heat into the surrounding air.

- Works well for light-duty vehicles under normal conditions.

Plate and Fin Coolers

- Compact design with increased surface area.

- Fluid passes through plates stacked with fin layers in between.

- Higher efficiency than tube and fin.

- Common in mid-range to performance vehicles.

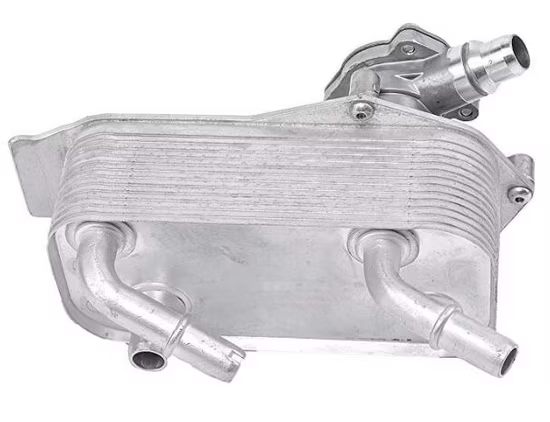

Stacked Plate Coolers

- Most efficient cooler type.

- Composed of thick, stacked plates with internal turbulators to increase fluid turbulence and heat transfer.

- Ideal for heavy-duty applications like towing, racing, or off-road driving.

In-Radiator (OEM) Coolers

- Built into the radiator’s coolant tank.

- Cost-effective for basic heat control.

- Limited cooling capacity compared to external aftermarket coolers.

- Used in standard passenger vehicles by OEMs.

Remote Coolers with Fans

- Includes an integrated electric fan for forced cooling.

- Suitable for vehicles with limited airflow or high-performance applications.

- Can be mounted almost anywhere in the vehicle.

Construction and Design Features

- Core Section:

- Made up of tubes, plates, or stacked layers where the fluid passes.

- Optimized for maximum surface area for heat transfer.

- Fins:

- Aluminum fins are attached to the core for faster heat dissipation.

- Increases contact with air.

- Inlet/Outlet Connectors:

- Threaded or hose barbed fittings for fluid lines.

- Designed for leak-proof operation.

- Mounting Brackets:

- Provide structural support.

- Designed for easy installation in various vehicle models.

- Protective Coating:

- Corrosion-resistant coatings (e.g., anodizing or powder coating) for durability against road debris, chemicals, and moisture.

Materials Used

- Aluminum: Most common due to lightweight, high thermal conductivity, and corrosion resistance.

- Copper/Brass: Offers superior heat transfer; heavier and costlier—used in some aftermarket models.

- Stainless Steel: Used for fittings, brackets, or racing applications where high pressure or harsh environments are involved.

- Rubber/Metal Hoses: For fluid conveyance between the transmission and the cooler.

Key Benefits of Using a Transmission Oil Cooler

- Prevents Overheating: Maintains ideal fluid temperature even under heavy load or high-speed conditions.

- Extends Transmission Life: Reduces wear on transmission components by ensuring consistent fluid lubrication.

- Improves Fuel Efficiency: Keeps the system running smoothly, avoiding drag due to overheated or degraded oil.

- Supports Towing & Heavy Loads: Essential for trucks and SUVs that haul trailers or cargo over long distances.

- Enhances Transmission Performance: Ensures smooth gear shifting and reduces risk of transmission failure.

- Reduces Maintenance Costs: Lowers chances of transmission breakdowns and expensive repairs.

Typical Applications

- Passenger cars (especially automatic transmission vehicles)

- Pickup trucks and commercial vehicles

- SUVs used for towing or long drives

- Racing and performance vehicles

- Off-road vehicles and ATVs

- Buses and logistics vehicles

- Emergency service vehicles (fire trucks, ambulances)

- Industrial and construction equipment

Performance Considerations

When selecting a transmission oil cooler, consider:

- Vehicle Size & Power Output

- Towing Capacity

- Typical Driving Conditions

- Mounting Space Availability

- Compatibility with existing transmission system

Auto Transmission Oil Cooler is not just an optional upgrade—it is a critical component that directly impacts the health, efficiency, and longevity of a vehicle’s automatic transmission system. As driving conditions become more demanding—whether due to towing, traffic congestion, long-distance driving, or performance applications—the need to control transmission fluid temperature becomes paramount.

By effectively removing excess heat from the transmission fluid, a quality oil cooler:

- Prevents overheating and breakdown of ATF,

- Enhances vehicle performance under load,

- Minimizes wear and internal damage to gears and clutches,

- And ensures smooth gear shifting and long-term reliability.

Choosing the right type of cooler—whether tube and fin, plate and fin, or stacked plate—should be based on your specific vehicle usage, load conditions, and space availability. When properly installed and maintained, a transmission oil cooler is a smart investment that can save you from costly repairs and premature transmission failure.