Introduction

Anti-Biofouling Tower System has emerged as an advanced solution that integrates cutting-edge disinfection technologies, self-cleaning mechanisms, and intelligent monitoring systems. These systems work proactively to prevent microbial accumulation, ensuring that cooling towers operate at optimal efficiency with minimal maintenance requirements. By implementing solutions such as UV disinfection, copper-silver ionization, ozone treatment, and AI-driven monitoring, industries can significantly improve energy efficiency, reduce water wastage, and extend equipment lifespan. With growing concerns about environmental sustainability and regulatory compliance, industries worldwide are shifting towards eco-friendly alternatives to chemical-based treatments. The Anti-Biofouling Tower System represents a step forward in this direction, offering a reliable, cost-effective, and environmentally responsible approach to cooling tower maintenance. This technology not only enhances performance but also aligns with modern sustainability goals by reducing the use of harmful chemicals and promoting efficient resource utilization. Cooling towers play a critical role in industrial and commercial facilities by dissipating excess heat from cooling processes. However, one of the most persistent challenges faced by these systems is biofouling, which occurs due to the uncontrolled growth of bacteria, algae, and other microorganisms.

Key Features & Technologies

- Ultraviolet (UV) Disinfection

- UV-C light is used to destroy bacteria, viruses, and other microorganisms in the water circulation system.

- The high-energy UV radiation disrupts the DNA of microorganisms, preventing them from reproducing and forming biofilms.

- Unlike chemical treatments, UV disinfection does not introduce harmful byproducts into the water, making it an environmentally friendly solution.

- Copper-Silver Ionization

- This method releases positively charged copper and silver ions into the water to eliminate microbial growth.

- Copper ions interfere with the cell membranes of bacteria, while silver ions disrupt their enzymes, leading to cell death.

- It is particularly effective against Legionella bacteria, which pose a serious health risk in cooling towers.

- The process requires minimal chemical intervention and provides long-lasting antimicrobial effects.

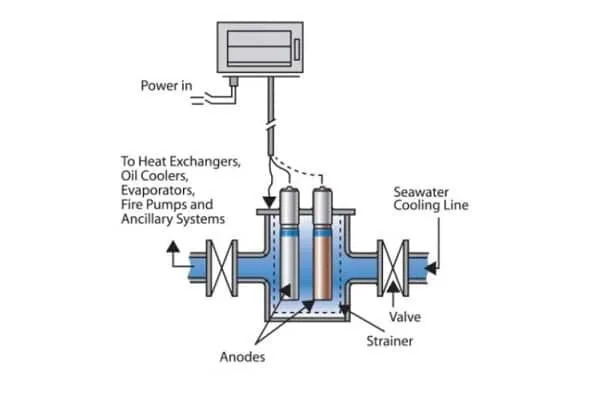

- Electrolytic Water Treatment

- Electrolytic treatment involves passing an electric current through the water to break down organic contaminants and inhibit the formation of scale and biofilms.

- The electrical charge alters the surface charge of suspended particles, preventing them from adhering to surfaces within the cooling system.

- This process also generates reactive oxygen species, which help oxidize organic matter and kill microorganisms without using chemical biocides.

- Self-Cleaning Nozzles & Drift Eliminators

- Specially designed self-cleaning nozzles prevent blockages caused by debris, algae, and biofilm accumulation.

- These nozzles maintain uniform water distribution, which helps in reducing stagnant areas where biofouling can thrive.

- Drift eliminators are also treated with antimicrobial coatings to prevent microbial growth and ensure cleaner air discharge from the tower.

- Ozone Treatment

- Ozone is a powerful oxidizing agent that effectively eliminates bacteria, viruses, and organic contaminants.

- It is generated on-site and injected into the cooling water, where it breaks down biological matter and prevents biofilm formation.

- Unlike chlorine-based disinfectants, ozone decomposes into oxygen without leaving harmful residues, making it a sustainable and safe solution.

- Hydrophilic & Anti-Adhesion Coatings

- Special coatings applied to cooling tower components prevent microbial attachment and biofilm development.

- Hydrophilic coatings create a water-repelling surface, making it difficult for bacteria and algae to settle.

- Anti-adhesion coatings contain antimicrobial agents that actively inhibit microbial colonization, reducing the need for frequent cleaning and maintenance.

- Smart Monitoring & AI-Based Control

- Advanced IoT-based sensors continuously monitor water quality, biofilm accumulation, bacterial activity, and overall system performance.

- AI-powered algorithms analyze real-time data and adjust disinfection levels, chemical dosing, and maintenance schedules accordingly.

- Predictive analytics help identify potential biofouling issues before they escalate, reducing downtime and optimizing operational efficiency.

Benefits of Anti-Biofouling Tower Systems

- Enhanced Heat Transfer Efficiency

- Biofilm buildup acts as an insulating layer, reducing heat exchanger performance and increasing energy consumption.

- By preventing microbial growth, the system maintains optimal thermal conductivity, ensuring efficient heat transfer.

- Lower Maintenance Costs

- Traditional cooling towers require frequent cleaning, chemical treatments, and manual interventions to remove biofouling.

- The anti-biofouling system significantly reduces these maintenance efforts, lowering operational costs and extending equipment lifespan.

- Improved Water Conservation

- Biofouling leads to increased water blowdown and wastage as operators must frequently replace contaminated water.

- With effective biofouling control, water usage is optimized, reducing overall consumption and promoting sustainability.

- Eco-Friendly Operation

- The system minimizes the use of hazardous chemicals such as chlorine and biocides, which can be harmful to the environment.

- By integrating ozone, UV, and ionization treatments, cooling towers can operate with minimal chemical dependency, reducing their ecological footprint.

- Extended Equipment Lifespan

- Corrosion and scaling caused by biofouling lead to premature wear and tear of cooling tower components.

- The anti-biofouling system prevents these issues, ensuring a longer operational lifespan for heat exchangers, pumps, and pipes.

- Legionella Prevention

- Cooling towers are a known breeding ground for Legionella bacteria, which can cause Legionnaires’ disease.

- The advanced disinfection and monitoring technologies in the system actively eliminate Legionella risks, ensuring compliance with health and safety regulations.

Future Trends & Innovations

- Graphene-Based Antimicrobial Coatings

- Graphene, a nanomaterial known for its exceptional thermal and electrical properties, is being explored for antimicrobial applications.

- Its unique surface structure prevents bacterial adhesion, making it a promising material for biofouling-resistant cooling tower components.

- AI-Powered Predictive Maintenance

- Advanced AI algorithms analyze vast amounts of operational data to predict biofouling trends and optimize cleaning cycles.

- This approach reduces unnecessary maintenance efforts while ensuring the system remains in peak condition.

- Biodegradable Anti-Fouling Agents

- Research is underway to develop natural, biodegradable compounds that can inhibit microbial growth without harming aquatic ecosystems.

- These alternatives aim to replace synthetic chemical biocides, making cooling tower operations more environmentally responsible.

- Microbubble Technology

- Microbubble aeration systems introduce ultra-fine air bubbles into the cooling water, disrupting bacterial biofilms and improving oxygenation.

- This technique enhances biological control while supporting energy-efficient cooling tower operation.

- Hybrid Cooling Tower Designs

- Future cooling systems are integrating dry and wet cooling technologies to minimize water exposure and biofilm formation.

- Hybrid designs optimize energy use, reduce environmental impact, and improve long-term operational reliability.

Conclusion

Anti-Biofouling Tower System is transforming cooling tower operations by addressing one of the most pressing challenges—microbial contamination. Traditional cooling systems require frequent chemical treatments, costly maintenance, and water-intensive operations to manage biofouling, which can lead to higher operational costs and environmental concerns. However, the adoption of innovative biofouling control technologies has paved the way for more efficient, cost-effective, and sustainable cooling solutions. By integrating advanced disinfection methods, self-cleaning components, and AI-powered monitoring systems, the Anti-Biofouling Tower System significantly enhances cooling tower performance. These advancements result in improved heat transfer efficiency, reduced downtime, extended equipment lifespan, and lower environmental impact. Moreover, the development of future innovations such as graphene-based coatings, microbubble technology, and biodegradable antifouling agents promises to make biofouling control even more efficient and sustainable. As industries continue to prioritize energy efficiency, water conservation, and regulatory compliance, the demand for Anti-Biofouling Tower Systems is expected to grow. Investing in these state-of-the-art solutions is not just a matter of operational efficiency but also a strategic move towards sustainability, cost savings, and long-term reliability.